Completing the chores that come with owning or running a horse farm can turn into a true daily grind if mud mayhem is added to the experience. But the presence of mud on the horse farm is more than just an inconvenience, it is a safety issue too.

Mud can cause a bevy of issues with equine health including pulled suspensory ligaments, slip and slide stifle and tendon injuries, mud fever/scratches and even broken bones.

In addition to the risk of mud causing injury to the horse there is also the risk of harm to the human contingent. A person may be knocked off their feet as a result of errant behavior of a horse that refuses to cross an area of mud/water, or an individual could fall down on ice patches that develop on puddles of water during cold winter months.

Ideally, plans for drainage, inclines, and aprons, guttering and discharge for run-off and footing for high traffic areas were executed during the original construction because it is more cost effective to have these aspects included during the site preparation phase with a follow up after construction than to have to retrofit drainage.

There are many expensive solutions to avoiding any puddles, ruts, or likelihood of mud mayhem around the horse barn. Topsoil and subsoil may be removed (even though the layers may be several feet deep), to expose the bedrock or clay pack beneath. Drainage can be constructed to remove water from any points of collection, with pipes sandwiched between geotextile fabrics and washed gravel. More gravel may be added on top, then another layer of smaller stone gravel on top of that and then compacted stone dust may be used as final layer to provide a hard surface. Certain high traffic areas may be ‘gridded’ with a permanent heavy-duty plastic or rubber grid mat system that is backfilled with a well-draining aggregate that neatly keeps all the materials in place.

Where driveways and entranceways traverse gradients, their topography can be carefully cambered to avoid heavy rain from washing out aggregates.

As you might expect, different companies have different approaches to the mud management problem and of course their own product line will be touted as the perfect answer to address the issue.

Be aware that rubber mats can become slick when wet, and that improperly covered grid systems can also be slippery under hoof for animals trying to get up and down from the ground. It is essential to follow the manufacturer’s guidelines accurately for the installation and use of such systems.

Many horse property owners are not building new barns with a clean slate of property on which to start development. For most folks mud management is a renovation project of areas around the barn entranceways and parking lots and paddock gateways that is needed to remove unwanted water collection points. Whichever the case, mud and surface water are essential.

Geology and Geography 101

Remedial actions to counteract damaged topsoil and subsoil layers and even address bedrock or hard pack damage are always possible.

You don’t need to understand the ‘horizon’ layers within soil, learn the 12 strata of soil and understand its development to know that the geology, climate, topography, and many other factors make every horse property mud management issue a project that needs to be addressed on an individual basis. No two properties are the same.

There are many other variables to appraise in the project to consider how the site is used. Reviews of traffic patterns across the property, amount of hoof traffic, breeds of horses housed, (consider the toll a draft horse or Gypsy Vanner horse boarding operation takes on the ground surface versus keeping a herd of miniature donkeys).

Temporary mud mitigation methods that utilize non-sustainable materials such as wood chips and sand, or even manure over ice patches, may be helpful for emergency use. Be cognizant that horses can inadvertently ingest sand with their forage and feedstuff if their food source is placed directly on sand. As this can cause the horse major digestive issues it is prudent to avoid the use of sand in feed areas where possible.

Wood chips and bio-degradable products will eventually dissipate, and their functionality will rapidly decline over time.

Water Is the Enemy

When it comes to jumping over the mud management fence the first hurdle to overcome is to remove as much direct water from the areas where it is likely to collect as possible.

Obvious topographical aspects such as the base of hills, construction induced water collecting spots such as run-off from a building’s roof, and low lying/poorly drained soil (easy to tell by the hummocky or reed like grasses and weed cover that enjoy them such as crabgrass, chickweed, sedges, etc.), will need a thorough examination and mapping out.

Wherever water flows, mud and possible flooding will follow. Take a hard look at your property after a heavy dowsing with rain or melting of snow, and you will easily identify the culprit areas that need significant action. Diversion of water flow from under the surface of the ground is the best way to deal with these issues. Remember saturated ground will not drain, and neither will ground that has an impervious surface such as concrete.

Read our Blog: “Why Did You Put It There?”! Avoid the Top 10 Critical Mistakes When Choosing Your Barn Location.

Commonly used drainage methods include French/footer/trench drains, or open swale drains and usually a combination approach is best in the overall design. Many of these options can easily be retrofitted to an existing horse farm. But for a major renovation or large construction project optimal results will be realized in mud management by employing a consultant well-versed in landscape design.

The Ubiquitous French Drain

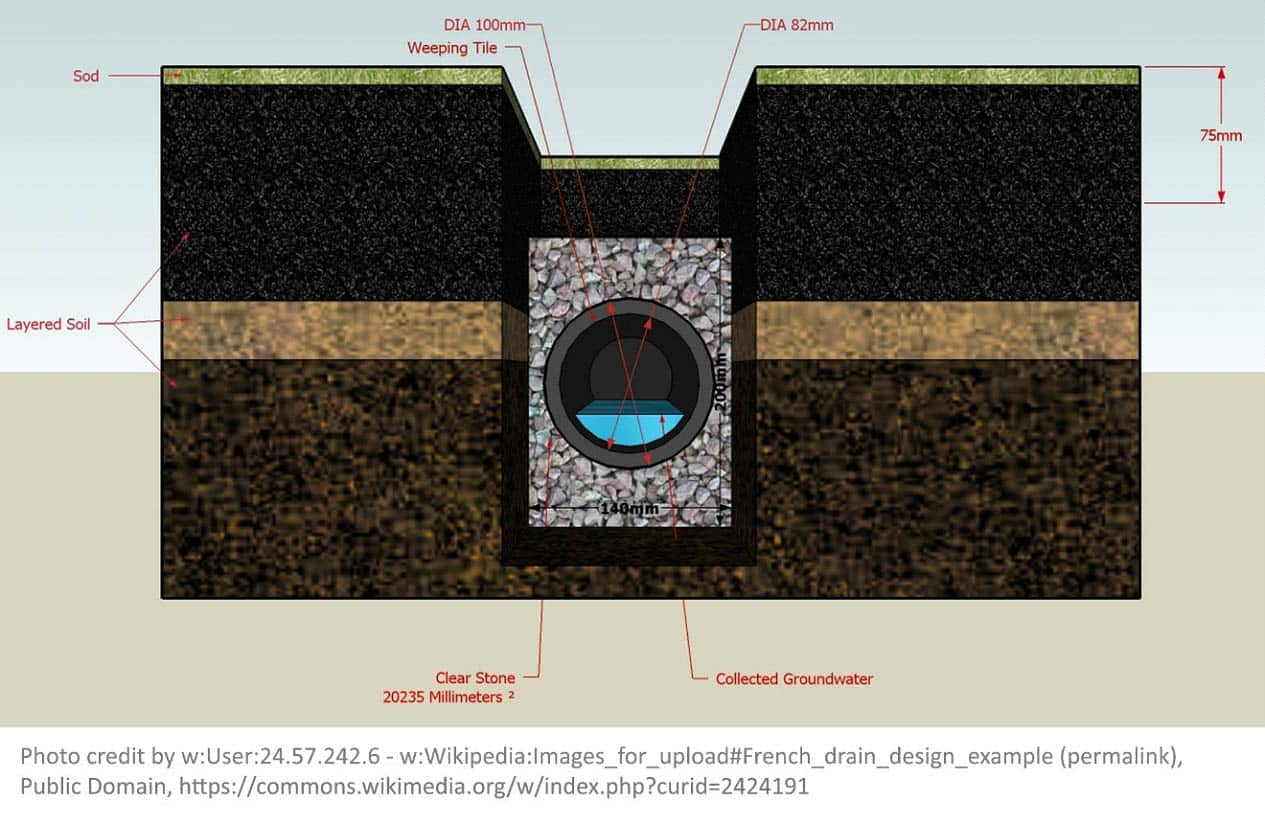

The French drain is ideally composed of a simple system that sandwiches a perforated PVC pipe between layers built like this:

- Dirt

- Geotextile Fabric

- Washed Gravel (it is cleaned so that it does not contain any stone dust as this would eventually block the fabric and the pipe holes)

- Perforated Pipe (holes on one side with pipe to be placed with holes facing down)

- Washed Gravel

- Geotextile Fabric

- Dirt

However, this system will only be effective at moving water along the channel if the pipe is placed at a specific grade where gravity can do the work. The magic number for grade is one percent i.e., for every 10’ of pipe the ground should slope at least one inch. Obviously, this grade should be inclined up to any building or specific area from which the water is desired to be removed. But where does the water then go?

The usual method to address the exit of water from the pipes is to take the pipes to daylight, into a small swale to continue to redirect the water away from the area.

Ditches can also be utilized, though consider how the ditches and pipe ends will be kept clear of damage and debris.

Other options include the use of a dry well or a yard drain system. A dry well is simply a large empty box in the ground that will collect excess surface water. Yard drains require much planning and are basically a catch basin with a sewer type system that collects the water from various locations and discharges it through a network of pipes to another area.

Be Careful What You Bury and How You Bury It

In high traffic areas care must be taken to bury the geotextile fabric sufficiently to ensure it does not become damaged by surface activity such as tractor tires, shod horse feet or pawing horses.

All drains should be carefully placed, and large areas should be covered with a deep level of gravel both above and below the fabric. Similarly grid systems must be protected from superficial damage.

If you desire to fill a low-lying area, be careful about how you fill it. Cheaper aggregates such as rip-rock or large boulders may seem a budget worthy solution to address the need for large cubic footage of fill. But despite the addition of gravel or other aggregates and their compaction over these materials to provide a smooth surface, the boulders and large shaped sub-surface will ultimately cause potholing of driveways and provide a bumpy footing and irregular surface as the smaller materials find their way through the cracks and crevices in the larger rocks and the variant materials compact at different rates.

It is better to opt for installation of shale or other similar aggregate that will break down over time and that will compact evenly, coated with gravel and other layers of materials to provide a smooth surface.

Hazards of Fill

It is essential to know the provenance of any fill materials or aggregates you bring on to your property. Fill can contain various contaminants, as well as hazards such as plastic bags or wood and metal. Run-off from hazardous fill can invade the groundwater supply, contaminate water sources including wells, and bring nefarious invasive species of plant life on to the property.